DATE

Interstellar Technologies Signs Three-party Business Alliance with Toyota Motor Corporation and Woven by Toyota

CATEGORY

TAG

- Interstellar Technologies, Toyota Motor Corporation and Woven by Toyota have entered into a three-party business alliance.

- This alliance will allow Interstellar to leverage automotive business assets to strengthen areas such as engine and propellant tank manufacture, as well as development of a comprehensive production system.

- Interstellar will also become the first startup to join Toyota Woven City’s Inventor.

Tokyo (Japan), August 4, 2025 – Interstellar Technologies (“Interstellar”), a leading space infrastructure company, has signed a three-party business alliance with Toyota Motor Corporation (“Toyota”) and Woven by Toyota (“WbyT”). The three parties will work together to establish a robust production system that enables frequent and cost optimized space transportation.

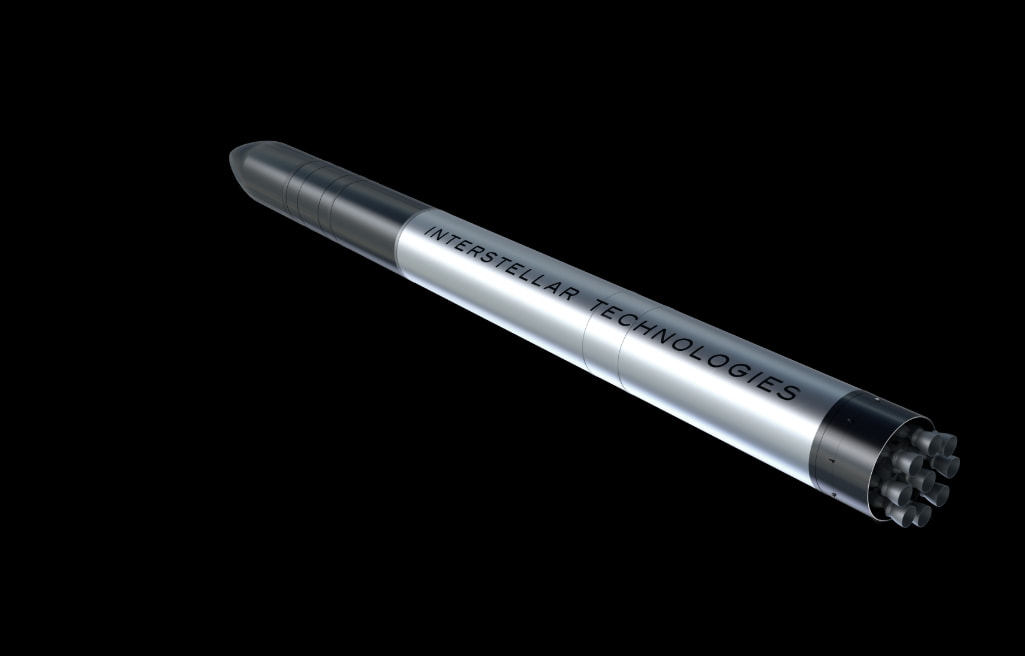

Interstellar, a pioneer in private space transportation in Japan, was the first domestic private company to reach space with its suborbital vehicle, MOMO. The company is currently developing ZERO, an orbital vehicle designed to launch small satellites in response to the global shortage of launch capacity and in alignment with the Japanese government’s goal to enhance domestic launch capabilities .

An alliance between Interstellar and the Toyota Group was initially announced in January 2025 when Interstellar and WbyT entered into a two-party strategic capital and business alliance. Now, building on that foundation, Interstellar, WbyT, and Toyota have signed a three-party business alliance agreement to advance vehicle development from one-off production to industrial-grade systems capable of supporting frequent launches.

As part of the new agreement, Toyota will dispatch personnel starting in August 2025 to support Interstellar in a wide range of manufacturing efforts, from the development of ZERO’s first flight unit to broader business commercialization. Additionally, Interstellar became the first startup to join “Toyota Woven City” as an Inventor, leveraging Toyota’s decades of manufacturing expertise and strengths. The development of ZERO will continue to be based on Interstellar’s facilities.

Driving Space Progress with Automotive Industry Strength

Japan’s space development has traditionally faced significant constraints in capital investment and human resources, stemming from the limited size of its domestic market. Interstellar aims to build a development and production framework that challenges conventional norms in the space industry, accelerating its growth as Japan’s leading space transportation company, leveraging the Toyota Group’s decades of manufacturing expertise and broad automotive assets, such as facilities, technologies, supply chains, and talent.

The key areas strengthened by this alliance are as follows:

COSMOS engine

Interstellar has independently developed proprietary technologies for key engine system components, including the combustion chamber and turbopump. ZERO is equipped with a total of 10 engines, 9 on the first stage and 1 on the second, each incorporating these advanced systems. The turbopump, in particular, is considered one of the most technically demanding components to design and manufacture. In Japan, only a select few companies, including Interstellar, possess the capabilities to both design and produce such high-performance systems in-house.

Interstellar will collaborate with Toyota and its affiliate, Toyota Motor Hokkaido, a longstanding partner with expertise in the mass production of automotive transmissions. Together, they will manufacture engine key components, including the combustion chamber and turbopump, for ZERO’s first flight unit. Additionally the companies will co-develop new manufacturing processes to reduce costs and accelerate production timelines. This partnership aims to establish a stable, high-quality production system for future launches.

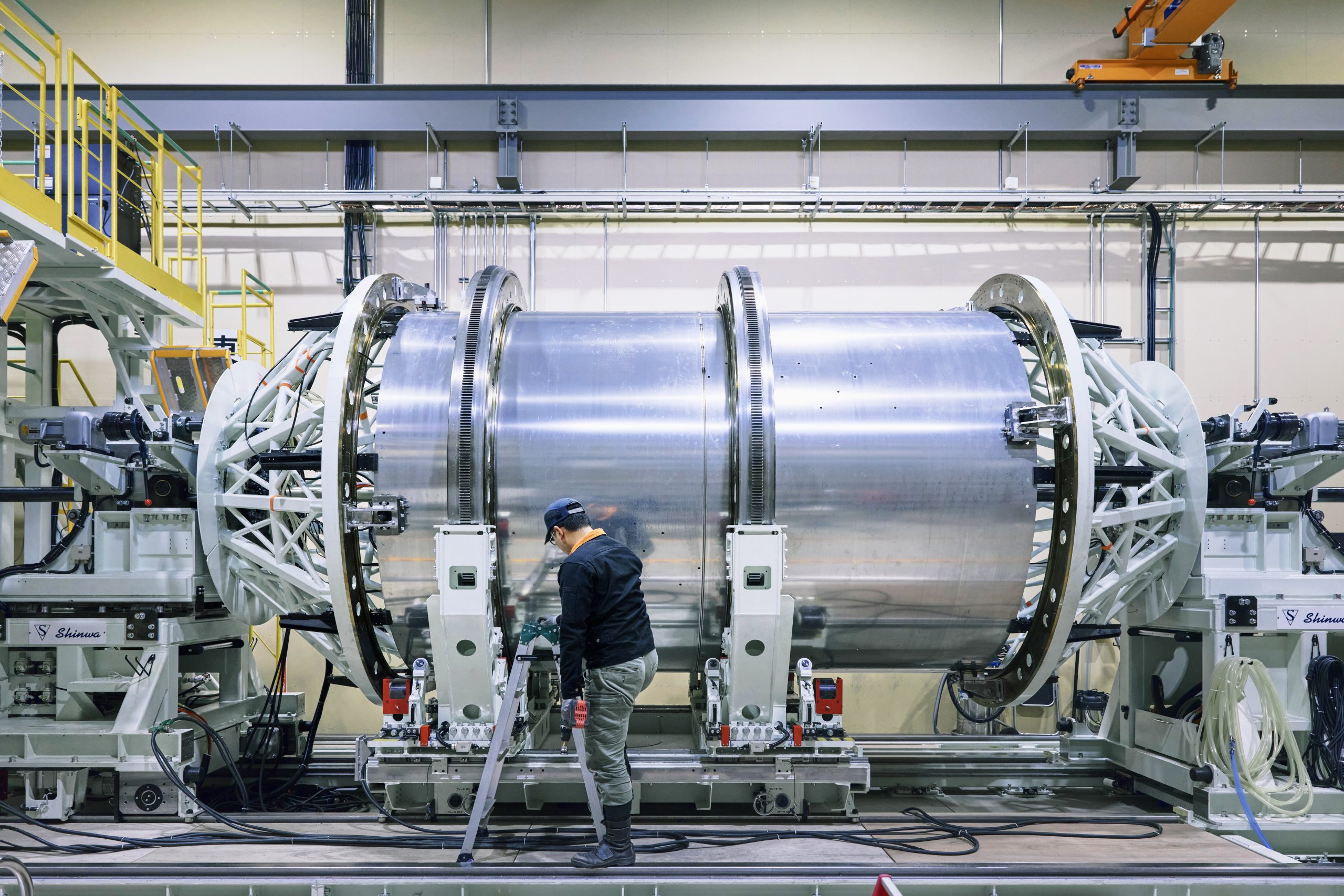

Propellant Tanks

Interstellar is currently designing, carrying key manufacturing processes and testing the propellant tanks for ZERO in-house. These tanks store liquid biomethane fuel and liquid oxygen oxidizer, and are made from A2219, a high-strength aluminum alloy that requires advanced welding techniques.

To further enhance vehicle performance through weight reduction, Interstellar and Toyota will collaborate on developing new manufacturing methods aimed at enabling high-frequency launches. These efforts will focus on cost reduction, shortening production timelines, and reinforcing the supply chain.

Comprehensive Production System

A single ZERO vehicle requires the coordination and supply of approximately 100,000 individual parts.

As Interstellar moves toward the launch of ZERO’s first flight unit, it will work closely with Toyota to leverage their automotive expertise and establish a comprehensive, efficient production system.

Toyota Motor Corporation

Woven by Toyota

Toyota Woven City

https://www.woven-city.global/

*1 A test course for mobility being developed by Toyota and WbyT in Susono, Shizuoka Prefecture.