DATE

Interstellar’s ZERO Succeeds in Propellant Tank Pressure Test

CATEGORY

TAG

Hokkaido, Japan – Interstellar Technologies Inc. (hereinafter referred to as “Interstellar”), a comprehensive space infrastructure company committed to tackling global challenges through space transportation and utilization, has reached a new milestone with the completion of propellant tank pressure testing for the small satellite launch vehicle ZERO (hereinafter referred to as “ZERO”) at the Interstellar’s testing facility in Taiki, Hokkaido.

The propellant tank, which underwent final stage welding at the main factory, was confirmed to have achieved its design strength. Interstellar progresses methodically towards ZERO’s first launch, handling the design, production, and testing of each components.

Securing High-Level Aluminium Welding Skills

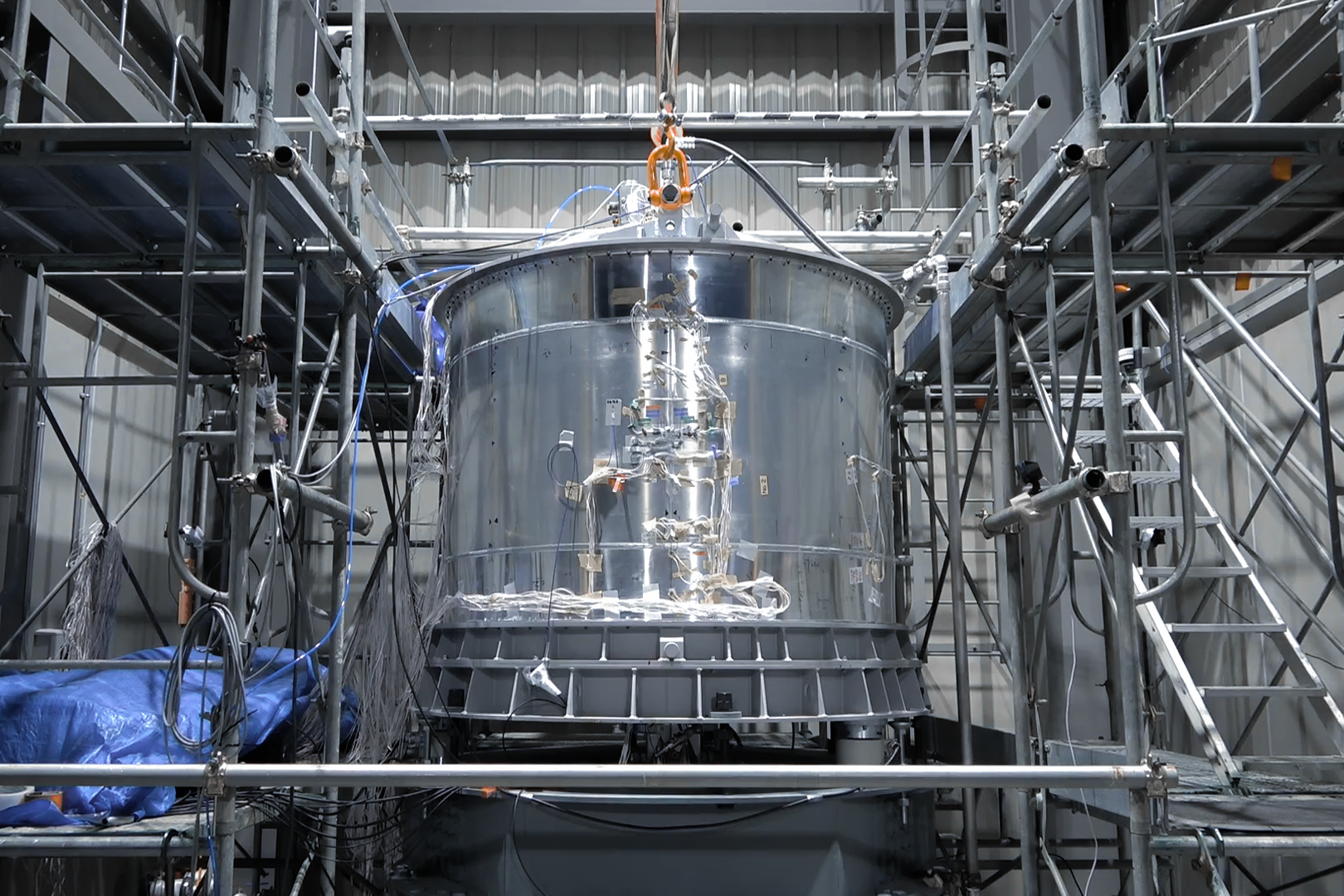

Interstellar takes charge of internally designing the propulsion tank to contain liquid biomethane fuel and liquid oxygen oxidizer. The adoption of a high-strength aluminium alloy (A2219) for the tank material requires advanced welding skills, and Interstellar manages the primary processes from welding to testing in-house. The tank used in this series of tests was a subscale model of the rocket’s second stage tank (1700mm diameter, 1731.5mm length , 3.5mm wall thickness), subjected to a Proof Pressure Test and a Burst Pressure Test to ensure its capability to withstand design pressures, in addition to a Burst test to gauge its pressure endurance limits. Subsequent phases will build upon the data obtained through these processes to propel the development and manufacture of a full-scale model.

【Propellant Tank Pressure Test Overview】

Test Name: Propellant Tank Test of Proof Pressure Test, Burst Pressure Test, and Burst Test

Objective: Verification of tank’s designed strength

Date & Time: December 11th and 13th, 2023

Location: Interstellar Technologies’ Structural Testing Facility (Taiki, Hokkaido)

Result of Test: Confirmed ability to withstand designed test pressures, obtained data on strength and failure modes

Second Stage Propellant Tank with Completed Welding

Second Stage Propellant Tank with Completed Welding

Observation during Pressure Test

Observation during Pressure Test

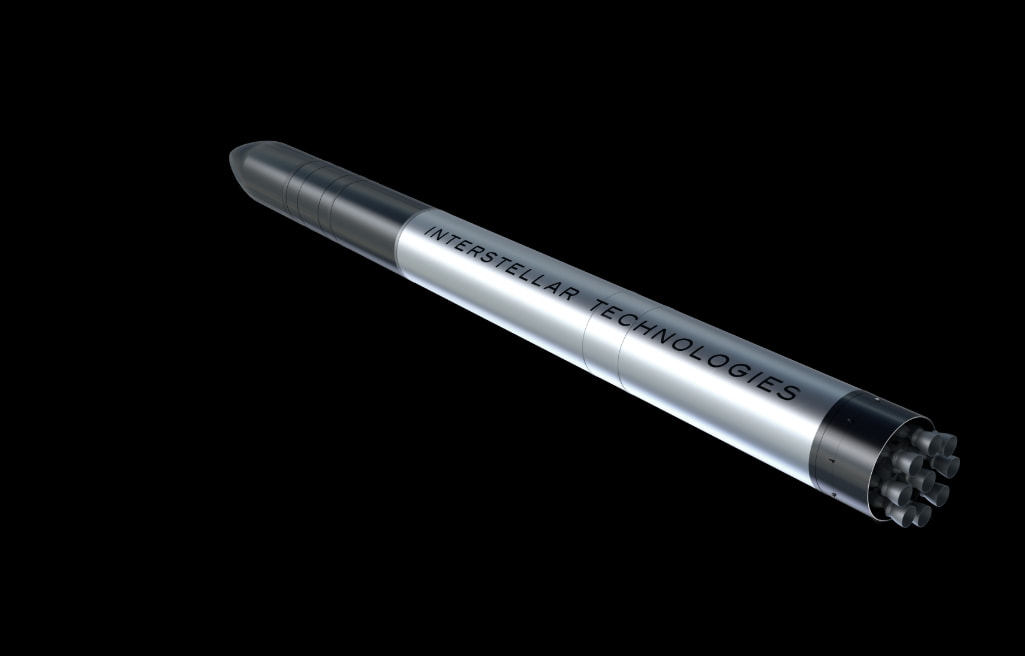

ZERO: Specifications

Height: 32m

Diameter: 2.3m

Wet mas: Weight: 71 ton

Propellant: Liquid Methane (Bio-Methane), Oxidizer: Liquid Oxygen

Number of Engines: 1st Stage: 9, 2nd Stage: 1

Payload Capacity: LEO 800kg / SSO 250kg (Future Maximum Capacity)

Competitive Pricing and Dedicated Launch Capability

ZERO is a small satellite launch vehicle designed to target the growing market for small-sized satellites in recent years. Building on the knowledge gained from the successful launch of the private suborbital launch vehicle ‘MOMO,’ the first of its kind in Japan’s private sector, Interstellar is progressing toward the first launch of ZERO.

ZERO’s space transportation service distinguishes itself with competitive pricing—at less than 800 million JPY per launch (in mass production)—made possible through an integrated development and manufacturing process. Another key strength is its flexibility to provide customized launches tailored to the rising needs of satellite companies. For satellite companies in Japan, Asia, and Oceania, proximity to the launch site ensures convenience, reducing launch-related time and costs and enhancing overall value.

ZERO’s Capacity Boost: To establish Asia-Oceania Market Presence

With an eye on recent trends and the demand both locally and globally, ZERO is enhancing its capacity to launch satellites of up to 800 kilograms into Low Earth Orbit (LEO). This strategic contributes to the establishment of an independent domestic space transportation service. Simultaneously, it positions Interstellar to establish a firm presence in the Asia-Oceania and European markets.

Press Release | 20230116_Interstellar’s ZERO Succeeds Propellant Tank Pressure Test