DATE

New Video “INSIDE ZERO Quality Control” Uploaded on our YouTube Channel

CATEGORY

TAG

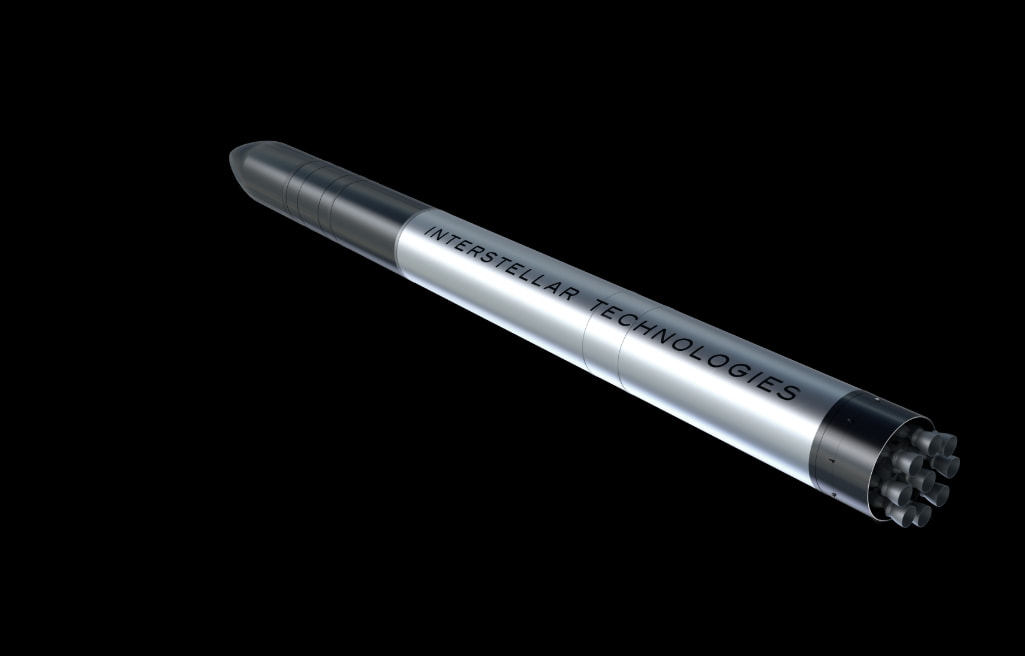

We have released a video showcasing the quality control process that ZERO’s components undergo on our official YouTube channel.

At Interstellar Technologies, quality control is at the heart of everything we do. Our orbital vehicle ZERO’s components undergo rigorous inspections at our headquarters in Taiki, Hokkaido, ensuring each part meets the highest standards during every step of development.

- Dimensional and geometrical measurement, to verify each part aligns precisely with design specifications

- Computed tomography (CT), to detect internal flaws without damaging the component

- Tensile testing, where welded propellant tank test pieces are pulled until they break to assess strength and durability

- Surface roughness measurement, to ensure optimal texture for mechanical performance and bonding quality