MANUFACTURED IN JAPAN

ZERO is a two-stage expendable launch vehicle developed in Japan, providing flexible space transportation through both dedicated missions and rideshare opportunities. Our focus is delivering your satellite to the right orbit, on your schedule.

SPECS

- MAX PAYLOAD WEIGHT

- LEO: 1,000 kg

- AVAILABLE INCLINATIONS

- 42.2° - SSO

- TOTAL LENGTH

- 32 m

- FAIRING HEIGHT

- 5.0 m

- VEHICLE MASS

- 71 t

2ND STAGE

Vacuum

Cosmos

engine ×1

2ND STAGE

Sea level

Cosmos

engine ×9

COSMOS ENGINE

ZERO’s engine is the first privately developed engine to use locally obtained liquid biomethane as propellant.

- PROPELLANTS

- Liquid Biomethane & Liquid Oxygen

- ENGINE CYCLE

- Gas Generator Cycle

- ENGINE COOLING

- Regenerative Cooling

- INJECTOR TYPE

- Pintle Injector

PAYLOAD CONFIGURATIONS

Zero supports various payloads, including small satellites and cubesats.

Sample configurations:

LATEST UPDATES

ZERO’S TESTING

OUR LAUNCH SITE

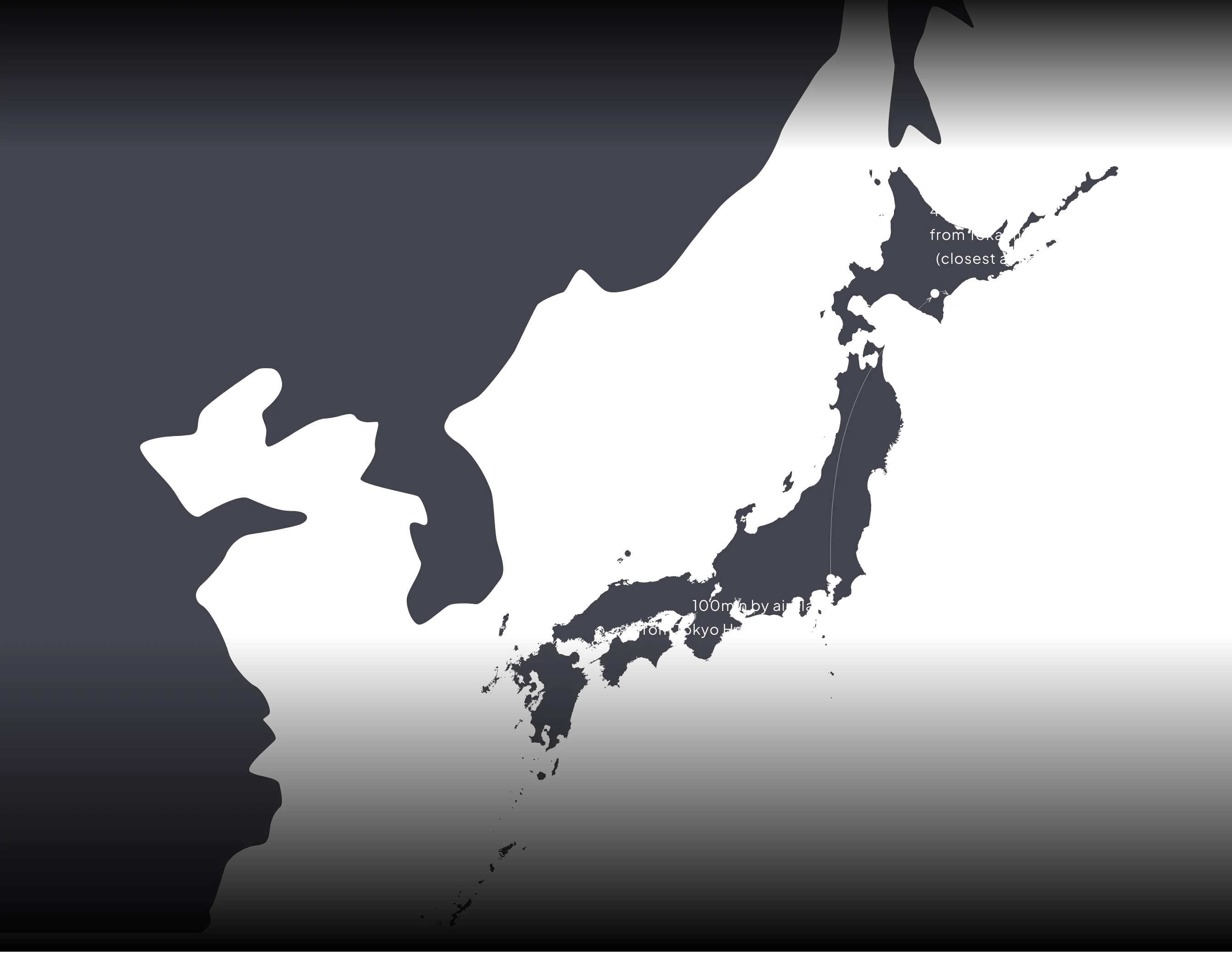

Hokkaido Spaceport (HOSPO), the designated launch site for ZERO, is located in Taiki town, in Hokkaido-Japan’s second-largest island and northernmost prefecture. HOSPO served as the launch site for Interstellar’s suborbital vehicle MOMO, which successfully reached space three times.

Apart from the launch site the complex features diverse facilities such as an static firing test site.

PERFECT LOCATION

Wide range of inclination with open sea to the east and south

CLOSE DISTANCE

15min by car from Interstellar’s headquarters and facilities.

CLEAR WEATHER

Favorable weather conditions that allow for accurate scheduling of launches.

POTENTIAL FOR SCALABILITY

The vast surrounding areas are available for future expansions.

LOOKING FOR

A LAUNCH VEHICLE ?

Payload User’s Guide is open to everyone, download it or book your flight below.